Automated workflow scheduling transforms manufacturing by replacing manual processes with software-driven efficiency. It uses real-time data and advanced algorithms to optimize production tasks, reduce waste, and improve delivery timelines. This approach eliminates bottlenecks, minimizes costs like overtime and material waste, and ensures machines and resources are used effectively.

Key Benefits:

- Increased efficiency: Automates repetitive tasks and reduces delays.

- Cost savings: Lowers inventory, energy, and labor expenses.

- Improved quality: Standardizes processes and reduces errors.

- Scalability: Handles complex operations and fluctuating demand with ease.

Implementation Steps:

- Analyze current workflows: Identify bottlenecks and inefficiencies.

- Select an ERP system: Choose a platform with strong scheduling features and real-time data integration.

- Train staff: Ensure employees understand and utilize the system effectively.

- Monitor and refine: Use data to continuously improve scheduling accuracy.

Automated scheduling, especially when integrated with ERP systems like Procuzy, enables smarter decisions by linking production planning with real-time inventory and demand forecasting. This shift not only boosts efficiency but also enhances customer satisfaction through reliable delivery and consistent quality.

Benefits of Automated Workflow Scheduling

Automated workflow scheduling has the power to revolutionize manufacturing operations, offering benefits that go far beyond just saving time. It creates a ripple effect, improving efficiency, cutting costs, and enhancing overall production quality.

Improved Efficiency and Productivity

One of the standout advantages of automated scheduling is how it eliminates the delays caused by manual processes. Instead of production managers spending hours juggling spreadsheets or coordinating resources over the phone, the system takes care of these tasks in a matter of seconds. This allows managers to focus on strategic decisions rather than getting bogged down with administrative work.

The system’s real-time visibility is a game-changer. Floor supervisors can instantly identify delays, spot machines nearing capacity, and address bottlenecks before they escalate. This proactive approach replaces the traditional reactive "firefighting" mode of management.

Machine utilization also gets a significant boost. By optimizing equipment use based on live data, the system ensures machines are consistently working. Idle time is reduced, and jobs are queued efficiently, balancing workloads across resources. The result? Lower costs and less waste.

Reduced Costs and Minimized Waste

Automated scheduling doesn’t just improve productivity – it also slashes operational expenses. For instance, inventory carrying costs drop because production schedules align more closely with actual demand. This reduces the need for excess raw materials and finished goods in storage.

Overtime costs also shrink as workloads are spread more evenly across regular shifts. Additionally, material waste decreases thanks to better coordination between production stages. Materials arrive exactly when they’re needed, cutting down on spoilage and eliminating rush charges from last-minute orders. This is especially beneficial for manufacturers dealing with perishable goods or components with limited shelf life.

Energy savings are another key advantage. By optimizing machine startup and shutdown sequences, the system avoids unnecessary energy use between jobs. It also minimizes energy-intensive startup cycles while still meeting production targets.

Setup and changeover times are reduced as well. The system intelligently groups similar jobs together, minimizing the frequency of machine reconfigurations. This not only saves time but also lowers labor costs and reduces production downtime.

Enhanced Quality and Growth Potential

Beyond efficiency and cost savings, automated scheduling contributes to better product quality and scalability. By standardizing workflows, the system ensures consistent processes, reducing variability and improving quality. For industries with complex assembly processes or strict regulations, this consistency is indispensable.

As production scales up, the system’s ability to handle complexity shines. Unlike manual scheduling, which often struggles with increased orders, product variations, or additional production sites, automated scheduling adapts seamlessly. It manages growing demand without requiring a proportional increase in planning staff.

During peak seasons or new product launches, the system adjusts resource allocation and timing to handle the added complexity while maintaining performance. Capacity planning becomes more accurate, thanks to detailed data on production rates, setup times, and resource use. This allows manufacturers to make informed decisions about equipment investments, staffing, and facility expansion.

Finally, customer satisfaction improves as manufacturers can provide more reliable delivery dates and fulfill orders more efficiently. Accurate delivery commitments and the ability to adapt to changes help build trust and stronger relationships with customers who rely on consistent supply.

How to Implement Automated Workflow Scheduling

Shifting from manual to automated scheduling requires careful planning, but the benefits can start to show within just a few months.

Review Current Workflows and Identify Issues

Before diving into automation, take a close look at how your current processes operate and where they’re falling short. Map out your production workflow, noting tasks, durations, responsibilities, and how work moves between departments.

Pay particular attention to bottlenecks and recurring issues. These might show up as frequent delays, constant overtime, or areas where employees spend too much time on manual coordination. Check your production data for patterns – are certain machines always overbooked? Are others underused? Do rush orders frequently disrupt your planned schedules?

Talking to the people on the ground – like floor supervisors, machine operators, and production planners – can uncover daily frustrations that reports might not reveal. Their input will help you pinpoint specific areas where automation can make the biggest impact.

Data collection is also essential at this stage. Gather historical production data, such as setup times, downtime, and resource usage. This information will serve as a baseline to measure improvements and ensure your new system is set up with realistic expectations.

These insights are key to choosing and configuring the right ERP system.

Choose and Configure the Right ERP System

Selecting an ERP system with strong scheduling capabilities is one of the most important steps in your automation journey. The system must meet your manufacturing needs and work seamlessly with your existing equipment and software.

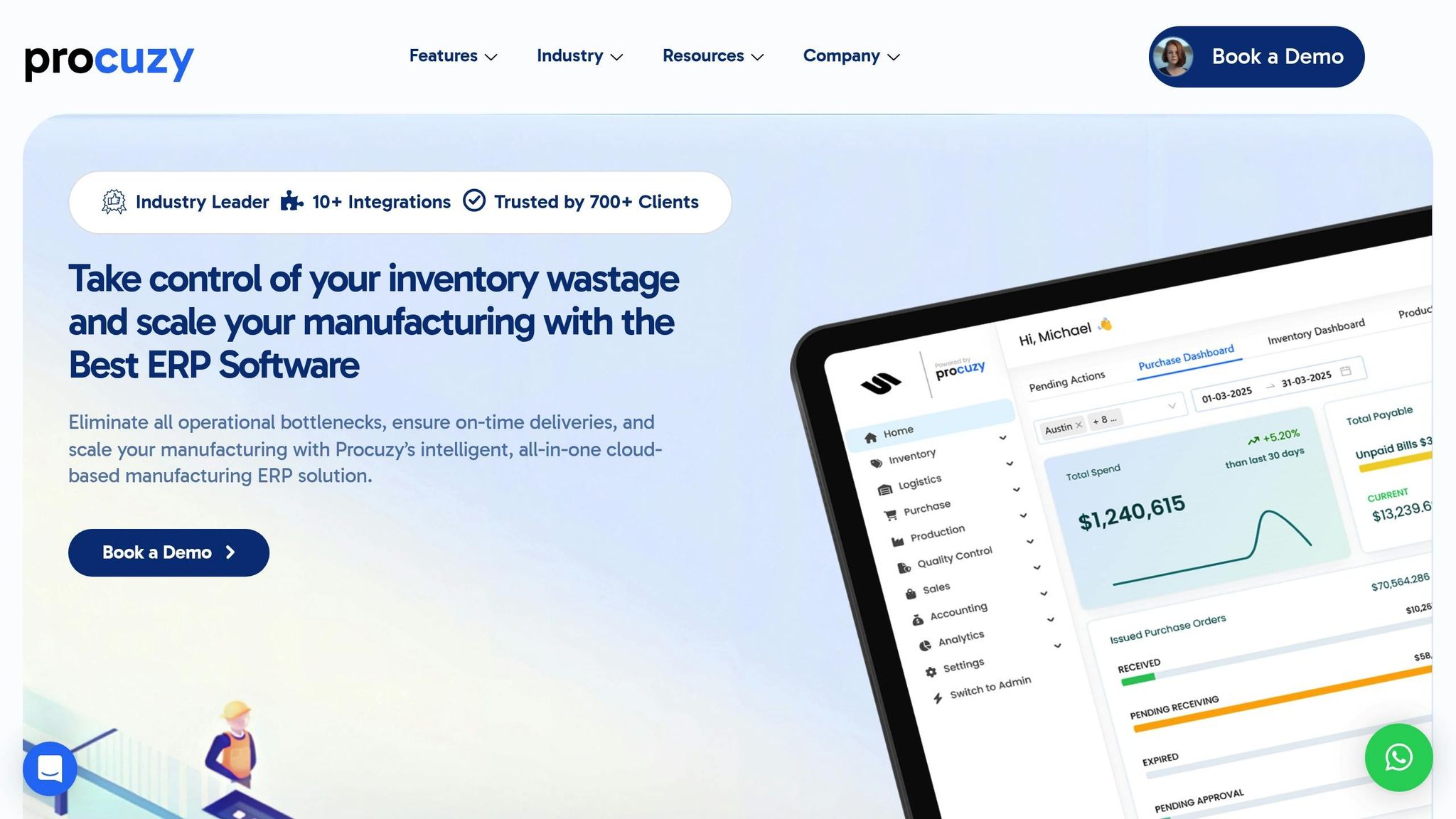

To address the bottlenecks you’ve identified, look for an ERP system that can adjust production flows in real time. For example, tools like Procuzy offer features designed specifically for workflow automation.

Start small by implementing a pilot program on a single production line or product family. This allows you to test and refine the system without risking disruptions across your entire operation. Configure the system with accurate details about your machinery, such as capacity limits, setup times, and maintenance schedules. Input your standard operating procedures and quality requirements so the system can make scheduling decisions that align with your operational constraints.

Integration with your existing tools is critical. Your ERP system should connect with accounting software, customer relationship management platforms, and any specialized manufacturing equipment. This ensures scheduling decisions are based on complete, up-to-date information, eliminating data silos.

Once the system is set up, the next step is ensuring your team is fully prepared to use it.

Train Staff and Monitor Progress

Even the most advanced automated system won’t succeed without proper training and user buy-in. Begin training well in advance of the system’s launch to address resistance and help staff see how automation will simplify their work.

Develop role-specific training programs instead of generic sessions. Production managers, for example, need to learn how to interpret automated schedules and make necessary adjustments. Machine operators should understand how to update job statuses and report issues. Administrative staff need to know how the system integrates with order processing and customer communication.

Focus on how automation will make their jobs easier. Highlight benefits like fewer last-minute schedule changes, reduced repetitive tasks, and less time spent chasing down information. Share concrete examples of how the system will improve their day-to-day work.

To track the success of your implementation, establish clear metrics. Monitor indicators such as schedule adherence, machine utilization, and order fulfillment times. Compare these metrics to the baseline data you collected earlier. Many manufacturers notice initial improvements within 4–6 weeks, with more substantial gains appearing after 3–6 months as staff become more comfortable with the system.

Set up regular check-ins during the first few months to identify and resolve issues quickly. Create a feedback loop where employees can report problems or suggest improvements. This ongoing communication helps the system evolve to meet your needs and ensures high adoption rates.

Progress tracking should include both numbers and staff feedback. While metrics like machine utilization rates provide valuable insights, understanding how employees feel about the changes can highlight areas for further improvement. Document lessons learned and best practices during this phase – they’ll be invaluable when expanding automation to other parts of your operation.

Effective training and consistent monitoring are essential to maximizing the benefits of automation while keeping the transition smooth.

Connecting Automated Scheduling with ERP Systems

Automated workflow scheduling becomes far more effective when paired with an ERP system. This integration transforms isolated scheduling efforts into a cohesive operation that adapts to dynamic changes across your entire manufacturing process. By leveraging insights from implementation, this connection bridges scheduling with broader operational insights.

Real-Time Data and Inventory Tracking

Linking your scheduling system to your ERP’s inventory management unlocks smarter, data-driven decisions based on real-time material availability. This integration eliminates the common problem of creating production schedules without knowing if essential components are out of stock or delayed.

With real-time inventory tracking, the scheduling system can automatically adjust production priorities when materials run low. For example, if a critical part for Product A is in short supply, the system can shift focus to jobs that use available resources while simultaneously generating purchase orders to address the shortage.

The integration also enables automatic stock alerts, flagging potential shortages well in advance. Instead of discovering missing materials mid-production, the system alerts procurement teams days or even weeks ahead, giving them time to source what’s needed without disrupting schedules.

For manufacturers operating across multiple locations, this connectivity is a game-changer. Integrated inventory systems allow the scheduling system to allocate resources more efficiently across all facilities, reducing delays often caused by disconnected systems.

Batch tracking is another standout benefit, especially for manufacturers with strict quality or regulatory standards. The system ensures materials from specific batches are used in the correct order, preventing quality issues and maintaining traceability throughout the production process.

Demand Forecasting and Resource Planning

ERP systems with integrated scheduling excel at turning historical data and current orders into precise production plans. Demand forecasting analyzes sales trends, seasonal patterns, and customer behavior to predict future needs with far greater accuracy than manual methods.

This forecasting feeds directly into resource planning, enabling manufacturers to allocate labor, machinery, and materials more effectively. The system can adjust schedules automatically to build inventory ahead of peak demand or, conversely, scale back production when forecasts indicate a slowdown. This ensures resources are used efficiently, aligning production with actual demand.

The integration also supports backward material planning from delivery dates, determining exactly when components need to be ordered or produced. This eliminates guesswork, reducing the risk of overstocking or running out of materials.

For manufacturers dealing with seasonal products or fluctuating demand, this capability is crucial. The system can scale production up or down as needed, ensuring profitability by spreading fixed costs efficiently across varying production volumes. By aligning production schedules with real-time demand, manufacturers can maintain a lean and responsive operation.

Example: Procuzy‘s Workflow Automation Features

Procuzy serves as a prime example of how seamless ERP integration can transform manufacturing operations. Its workflow automation features highlight the benefits of this integration in action.

Procuzy’s platform integrates inventory tracking, automated scheduling, and demand forecasting to ensure production decisions are always based on up-to-date material availability and accurate requirements.

With batch tracking and barcoding, Procuzy ensures materials are used in the correct sequence, maintaining full traceability. If a quality issue arises, the system can quickly pinpoint affected batches and identify where those materials were used in production.

Procuzy’s multi-location support optimizes resource allocation across facilities. If one location faces material shortages or capacity constraints, the system automatically redistributes work to other sites with available resources.

Additionally, business intelligence dashboards provide real-time visibility into scheduling impacts. Managers can monitor metrics like schedule adherence, resource utilization, and delivery performance, enabling them to fine-tune operations for better results.

Together, these features create a manufacturing environment where scheduling decisions adapt to real-time conditions, ensuring alignment with business goals while maintaining operational efficiency.

sbb-itb-a748ddd

Best Practices for Automated Workflow Scheduling

To truly benefit from automated workflow scheduling, you need more than just the right software. Manufacturers achieving real success follow specific strategies that transform their scheduling systems into game-changing tools. These approaches help sidestep common pitfalls and maximize the value of your automation investment.

Use Real-Time Production Data

Effective scheduling thrives on real-time data. By connecting your scheduling system to live production monitoring tools – such as sensors, machine controllers, and operator interfaces – you can capture accurate details like cycle times, material use, and quality metrics as they happen. This allows for instant adjustments when machines slow down, encounter issues, or finish tasks ahead of schedule.

Automatic alerts are a must-have feature. These alerts flag significant deviations from the schedule, providing managers with immediate notifications and recommended actions to address the problem. For example, if a machine unexpectedly breaks down, managers can quickly reallocate resources to minimize downtime.

In industries like food processing or pharmaceuticals, monitoring environmental conditions like temperature is critical. Automated systems can delay or reschedule production runs if conditions fall outside acceptable ranges, preventing costly quality issues before they arise.

Don’t overlook the value of operator feedback. Touchscreen interfaces allow workers to provide quick updates when they encounter problems that sensors might miss. This human input helps the scheduling algorithms adapt and improve over time, creating a smarter and more responsive system.

Real-time data lays the groundwork for consistent, efficient processes, which is where standardization comes into play.

Standardize Processes and Documentation

Real-time data is only as reliable as the consistency behind it. To enable accurate scheduling predictions, standardize and document every step of your production process. This includes setups, run rates, changeovers, work instructions, and quality checkpoints.

Material handling should also follow set protocols for receiving, storing, and issuing components. When these processes are consistent, your scheduling system can better predict material availability and align deliveries with production needs.

Keeping documentation up to date is equally important. Assign team members to revise standard procedures whenever changes occur. Outdated documentation can lead to scheduling errors and missed deadlines.

Training plays a key role in standardization. Ensure all operators understand the production processes and know how to interact with the scheduling system. When everyone follows the same procedures for updating job statuses, reporting issues, and requesting schedule changes, the system maintains accurate data and makes more informed decisions.

Improve Through Data Analysis

Once you’ve established real-time data collection and standardized processes, the next step is using data analysis to refine your scheduling. By monitoring metrics like on-time delivery, schedule adherence, and resource utilization, you can identify bottlenecks, improve setup times, and fine-tune scheduling parameters.

For example, bottleneck analysis pinpoints constraints that limit production capacity. Data from your scheduling system reveals where work tends to pile up and which resources are consistently overburdened. This insight helps guide decisions about equipment upgrades, staffing adjustments, or process changes.

Setup and changeover analysis often uncovers opportunities for improvement. Many manufacturers find that their default changeover times are either too cautious or too aggressive. Reviewing actual changeover data allows you to adjust these settings for more accurate scheduling.

Quality correlation analysis is another valuable tool. By examining how scheduling decisions impact quality, you might notice that rushing certain jobs increases defect rates or that specific machine combinations yield better results. This information helps the system balance efficiency with quality.

Cost analysis ties scheduling decisions to financial outcomes. Track how different approaches influence overtime expenses, expediting fees, and inventory costs. Use this data to adjust optimization algorithms, prioritizing the most cost-effective scheduling strategies.

Finally, seasonal pattern analysis is essential for manufacturers with cyclical demand. By studying historical data, your scheduling system can anticipate seasonal trends and automatically adjust capacity planning and inventory strategies to handle peak periods more effectively.

With regular adjustments based on performance data, your scheduling system stays sharp and continues to deliver better results over time.

Conclusion

Automated workflow scheduling takes production planning to the next level by turning it into a precise, data-driven process. By moving away from manual, error-prone methods and embracing automation, businesses can boost efficiency, lower costs, and improve overall quality.

Key Points Summary

To get started, identify the bottlenecks caused by manual scheduling and pinpoint areas where delays or inefficiencies occur. Automation makes a big difference by optimizing resource allocation, cutting down setup times, and reducing idle periods. Consistent processes managed by automated systems help maintain quality and avoid scheduling conflicts that could lead to rushed work or defects. Plus, as operations grow, these systems handle added complexity without piling on administrative burdens.

The success of implementing automated scheduling relies on a few critical steps: analyzing workflows thoroughly, integrating with ERP systems, and ensuring staff are well-trained. When scheduling tools are connected to inventory tracking, demand forecasts, and production monitoring, they provide a unified view that supports smarter, faster decision-making.

Standardized processes and continuous analysis are key to long-term success. Real-time production data ensures accurate scheduling, while ongoing adjustments based on data insights keep systems flexible and responsive to change.

Modern ERP platforms like Procuzy showcase how integrated scheduling tools can seamlessly work with inventory management, production planning, and demand forecasting. This type of integration breaks down data silos, offering a single, reliable source of information for production decisions.

These strategies provide a clear path toward achieving manufacturing success.

Next Steps

To stay competitive, now is the time to embrace automation. Begin by evaluating your current scheduling methods and identifying areas where inefficiencies or delays occur most often.

Explore ERP solutions that include robust scheduling features, particularly those that integrate seamlessly with your existing processes. Look for platforms offering real-time inventory tracking, automated notifications, and detailed reporting capabilities. Many businesses find that the investment in scheduling automation pays off within the first year.

Consider starting with a pilot project in one production area or product line. This approach allows you to fine-tune processes, train your team, and demonstrate the value of automation before expanding it across your entire operation.

In today’s fast-paced market, automated workflow scheduling is no longer optional – it’s essential. The question isn’t whether to adopt it, but how quickly you can implement it and start reaping the rewards.

FAQs

How does automated workflow scheduling work with ERP systems to boost production efficiency?

Automated workflow scheduling works hand-in-hand with ERP systems to take over repetitive tasks such as data entry, order processing, and approvals. This not only cuts down on manual effort but also accelerates operations and ensures that data stays accurate and up-to-date across your production processes.

By using real-time data to adjust production schedules on the fly, this integration helps reduce downtime, make better use of resources, and boost overall efficiency. The outcome? A smoother manufacturing process that’s more adaptable to shifting demands and supports continuous growth.

What are the essential steps to implement automated workflow scheduling in manufacturing?

To get the most out of automated workflow scheduling, start by taking a close look at your current production processes. Identify any inefficiencies, bottlenecks, or repetitive tasks that could benefit from automation. This initial evaluation helps you zero in on the areas where automation can make the biggest difference.

Next, select an automation system that works well with your existing ERP platform. For example, tools like Procuzy can ensure smooth data sharing and coordination across different departments. Planning is key here – create a clear step-by-step implementation strategy, train your team thoroughly, and introduce the system gradually to avoid major disruptions.

Once the system is up and running, keep an eye on its performance. Regularly monitor and fine-tune the workflows to ensure they stay efficient and aligned with your production goals. This ongoing adjustment helps you boost productivity while cutting down on wasted resources.

How does automated workflow scheduling enhance product quality and improve customer satisfaction?

Automating workflow scheduling helps refine production processes, cutting down on errors and ensuring a steady, reliable output. This consistency translates to better product quality that aligns with customer expectations.

On top of that, automation accelerates production timelines and improves delivery punctuality, which strengthens customer trust and loyalty. These benefits not only enhance customer satisfaction but also contribute to building lasting relationships and a reputation for dependability.