Demand forecasting helps manufacturers predict future customer demand and align operations accordingly. It improves production planning, inventory control, supply chain management, and financial planning, leading to better efficiency, reduced waste, and enhanced customer satisfaction.

Key benefits include:

- Efficient production: Prevents overproduction and stock shortages.

- Cost savings: Reduces excess inventory and storage costs.

- Customer satisfaction: Ensures timely product availability.

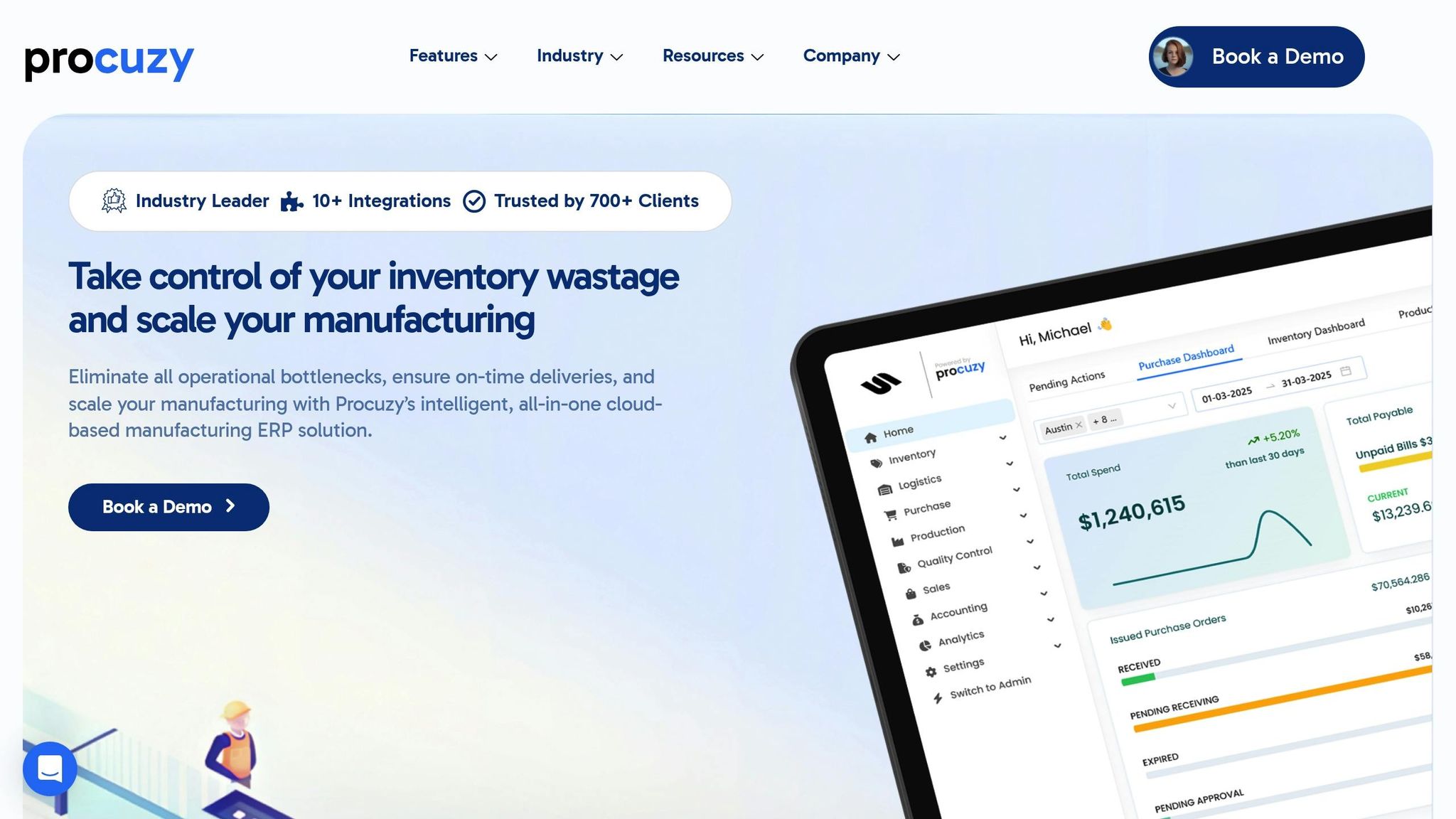

To achieve accurate forecasts, manufacturers use methods like data analysis, expert opinions, and AI-driven models, often integrated into ERP systems for real-time insights. Tools like Procuzy’s ERP enhance forecasting with features like real-time dashboards, automated alerts, and AI-powered predictions.

Quick Tips for Better Forecasting:

- Use clean and integrated data.

- Combine quantitative and qualitative insights.

- Leverage AI and machine learning for advanced predictions.

Start by analyzing historical data, integrating forecasting tools, and adopting flexible models to stay competitive in fluctuating markets.

Impact on Manufacturing Operations

Production and Inventory Control

Demand forecasting plays a key role in aligning production schedules and inventory levels. By analyzing historical data and market trends, it helps avoid costly issues like overstocking or running out of stock. Too much inventory ties up money and storage, while not enough leads to lost sales and unhappy customers. With accurate forecasting, manufacturers can keep inventory at just the right levels, ensuring production meets actual demand. These forecasts also help guide decisions about resource allocation and budgeting.

Resource and Budget Planning

With solid demand forecasts, manufacturers can allocate resources and plan budgets more effectively. Reliable projections make it easier to coordinate raw material purchases and streamline operations. For instance, companies can see a double-digit return on investment within three years by improving resource planning and operational efficiency. These financial benefits also enhance customer satisfaction and strengthen the company’s position in the market.

Customer Service and Market Position

Getting demand forecasts right has a direct impact on customer satisfaction and competitiveness. When production aligns with market demand, manufacturers can ensure products are consistently available and orders are fulfilled quickly. This not only keeps customers happy but also helps maintain a strong competitive edge.

To get the most out of demand forecasting, combine quantitative data with market insights, maintain open communication with suppliers and customers, work with multiple vendors, and use real-time sales data to adapt to changes quickly.

DEMAND FORECASTING Made Easy for Manufacturers

Forecasting Methods and Tools

Manufacturers typically divide forecasting into three main methods, each offering a unique approach to predicting demand and managing production.

Data-Based Methods

These methods rely on historical sales data, market trends, and statistical models like time series and causal analysis. By identifying demand patterns, manufacturers can better match production to market needs while keeping inventory levels under control.

Experience-Based Methods

This approach uses expert opinions, market studies, and customer feedback to guide predictions. It’s especially helpful when historical data is sparse or when markets are in flux.

Another experience-based approach, production-driven forecasting, focuses on manufacturing capacity and resource allocation. While it ensures efficient operations, it requires frequent market evaluations to stay aligned with actual demand. Many manufacturers combine this with pull systems, which prioritize real customer orders, to strike a balance between efficiency and flexibility.

AI and Predictive Models

AI models take forecasting to the next level by analyzing multiple real-time data sources – such as sales numbers, economic trends, and market sentiment. These models can uncover hidden demand patterns and continuously fine-tune predictions.

Key differences between approaches:

- Traditional methods rely on manual analysis and periodic updates, which can lead to inconsistent accuracy.

- AI models automate data processing, provide real-time updates, identify complex trends, and improve accuracy over time.

Best Practices for Forecasting:

- Test forecasting tools on a smaller scale before full implementation.

- Combine quantitative data with qualitative insights for a well-rounded view.

- Regularly compare forecasts to actual outcomes to refine predictions.

- Incorporate external factors like economic and market indicators for a broader perspective.

Finally, consider integrating these forecasting methods into your ERP system. This centralizes data and helps you respond quickly to changing market conditions.

sbb-itb-a748ddd

ERP Systems in Forecasting

After exploring AI and predictive forecasting methods, the next step is integrating them into an ERP system. This approach helps automate processes and scale insights effectively.

Procuzy’s ERP brings together data from sales, inventory, production capacity, supply chains, market trends, and seasonal factors into a single platform. This integration helps improve forecast precision by leveraging key inputs like:

- Historical sales and inventory data

- Production capacity and supply chain updates

- Market trends and seasonal influences

Procuzy Forecasting Tools

Procuzy offers a range of tools to enhance forecasting, including:

- Real-time dashboards: Track key performance indicators (KPIs) and demand trends.

- Automated stock alerts: Manage inventory across multiple locations.

- Batch tracking and custom workflows: Streamline processes tailored to specific needs.

Using these inputs, Procuzy’s AI engine refines forecasts, balances stock levels, and reduces storage costs.

Quick Response to Market Changes

Procuzy’s ERP is designed to help businesses adapt quickly to shifting market demands. Features include:

- Alerts for unexpected demand surges

- Real-time schedule updates

- Automated material requisitions

- Flexible capacity and resource allocation

- Schedule adjustments to meet demand

- Tools to monitor capacity utilization

Tips and Common Problems

Procuzy’s ERP tools streamline data flows, but these strategies can fine-tune accuracy and address forecasting challenges.

Improving Forecast Accuracy

Focus on Data Integration and Quality

Combine data from sales, production, and market sources. Regularly clean and validate this information to ensure it’s reliable.

Use AI and Machine Learning

AI and machine learning can identify patterns in historical, seasonal, and market data, helping to refine forecasts.

Encourage Cross-Functional Collaboration

Get teams from sales, production, and supply chain on the same page. Shared insights lead to better forecasting results.

Tackling Common Challenges

Here are some frequent forecasting problems and how to address them:

- Data Quality Problems: Use automated validation tools and perform regular audits to maintain clean data.

- Market Volatility: Build flexible models and plan for multiple scenarios to handle sudden changes.

- Integration Issues: Ensure data management systems across departments are connected and unified.

- Complex Demand Patterns: Leverage analytics tools designed to recognize and analyze intricate demand trends.

Keep Monitoring

- Compare actual demand to forecasts in real time for quick adjustments.

- Update production schedules immediately when discrepancies arise.

- Factor in economic trends, seasonal shifts, and consumer behavior for more dynamic forecasting.

Once your forecasts are on point, you’re ready to dive into practical applications in the next section.

Industry Examples

Manufacturing Success Stories

Church Brothers Farms, a major player in the food and beverage industry, improved its short-term forecast accuracy by 40% with AI-driven demand sensing [1]. By focusing on the "5 R’s" – right stock, right quantity, right cost, right time, and right location – they significantly reduced waste in an industry that discards an astounding 106 million tons of food every year [1].

Procuzy applies similar AI-based forecasting methods across multiple manufacturing sectors, helping businesses optimize operations.

Procuzy Across Industries

Procuzy’s demand forecasting tools support a variety of manufacturing sectors, each with unique challenges:

- Food & Beverage (F&B): Enables real-time inventory tracking and sends automated alerts to help balance stock and cut down on waste across multiple locations.

- Chemical Manufacturing: Offers batch tracking and quality control tools, ensuring better seasonal demand planning and compliance with regulatory requirements.

- Furniture Manufacturing: Supports material tracking, manages long lead times, coordinates workshop schedules, and adjusts forecasts to account for seasonal demand shifts.

Procuzy’s adaptable approach ensures manufacturers in these industries can efficiently manage resources and respond to market demands.

Summary

Here’s a quick recap and the key steps to start using demand forecasting with Procuzy effectively.

Key Takeaways

- Precise demand forecasting helps you allocate resources efficiently, cut costs, and adapt quickly to market shifts.

Steps to Get Started

- Prepare your data: Clean and standardize historical sales, market trends, and economic data.

- Integrate systems: Link Procuzy for real-time inventory tracking, alerts, quality checks, and planning tools.

- Choose the right models: Use a mix of time series, AI-based, and causal forecasting models, and update them often to improve accuracy.

To stay ahead in manufacturing, use multiple forecasting methods, update forecasts with fresh data, and track actual versus predicted demand. This approach ensures consistent improvements and keeps you competitive.