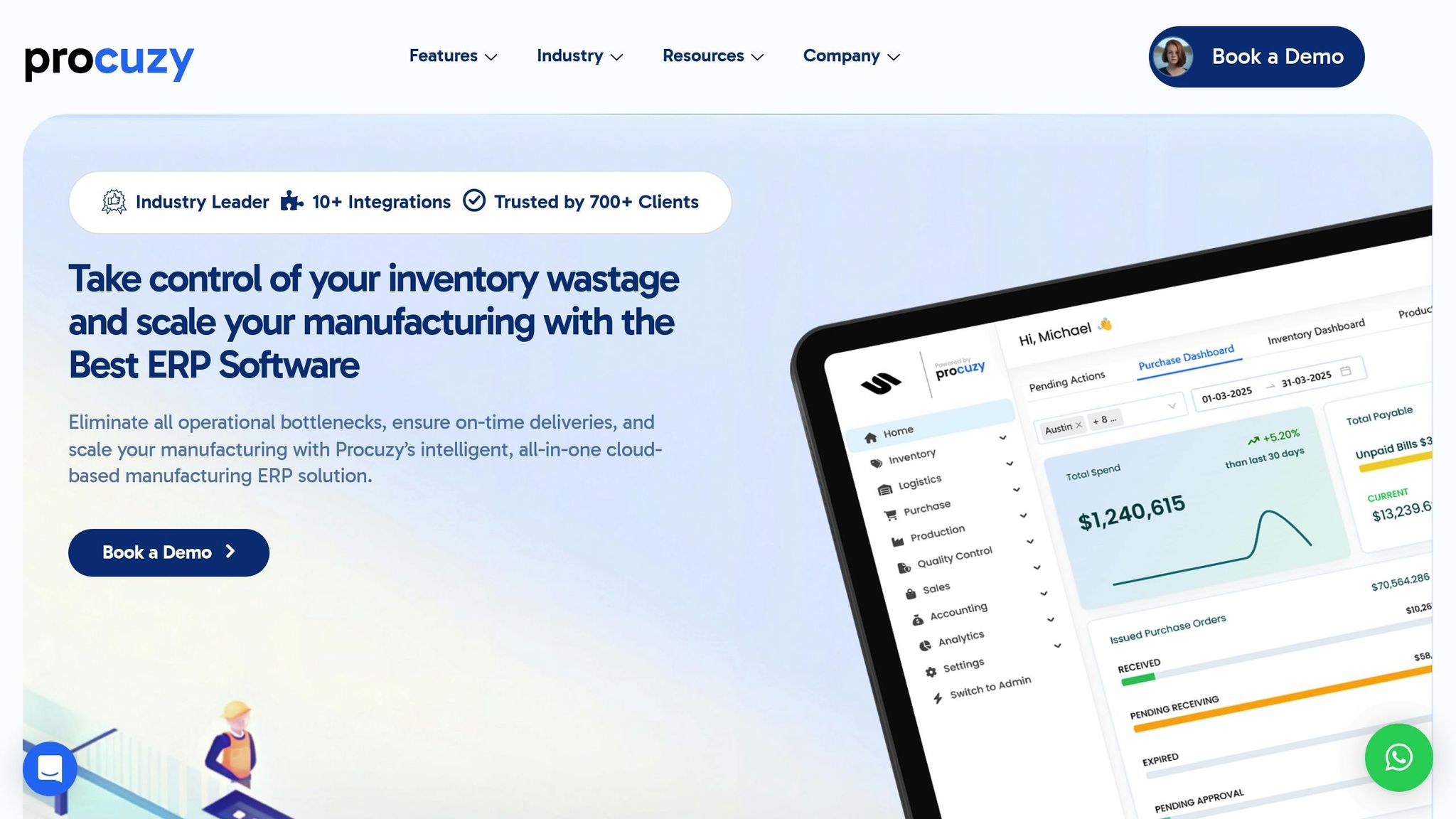

Manufacturers lose up to 30% of revenue due to inefficiencies and downtime. Procuzy ERP software solves this with tools that cut costs, reduce waste, and improve efficiency. Companies using Procuzy report:

- 60% less waste through smart inventory management.

- 1.5x faster production with automated workflows.

- 22% lower operational costs by optimizing resources.

Key features include real-time inventory tracking, accurate demand forecasts, and batch tracking for quality control. Procuzy integrates with existing systems, making it a practical choice for manufacturers of all sizes. Whether you’re managing strict regulations in pharmaceuticals, perishable goods in food, or complex materials in furniture, Procuzy simplifies operations and boosts profitability.

Quick Overview:

- Inventory Accuracy: Reduces manual errors by 68%.

- Demand Forecasting: Balances supply and demand to avoid overproduction or stockouts.

- Quality Control: Identifies defective batches in 4 hours, reducing recall costs.

- Setup: Tailored to your needs, with seamless integration and ongoing support.

Procuzy ERP is a single platform to modernize manufacturing, improve efficiency, and grow your business. Below, explore how it works across industries like pharmaceuticals, food, and furniture.

Key Procuzy ERP Software Features That Improve Production

Live Inventory Tracking

Procuzy’s real-time inventory tracking gives manufacturers an up-to-the-minute view of stock levels across all locations, ensuring accuracy and transparency. By using barcode scanning and RFID technology, the system automatically updates inventory data as materials move through your facility. Every transaction is logged instantly, cutting down on manual tracking errors by 68% in most cases. This streamlined approach helps detect excess inventory or potential shortages early, preventing costly disruptions. With live dashboards and automated updates, the system also minimizes waste and ensures accurate records across multiple sites. This level of control not only keeps stock in check but also supports better demand forecasting.

Demand Prediction and Production Planning

Armed with real-time data, manufacturers can fine-tune their production schedules with Procuzy’s demand forecasting tools. By analyzing historical data, market trends, and customer behavior, the system predicts future needs with precision. This helps balance supply and demand, avoiding overstock and stockouts. Procuzy processes inputs like sales orders, material requirements, and forecasts to optimize inventory and align production schedules. It even factors in supplier lead times and production capacities, creating realistic and achievable plans – a crucial advantage for industries with tight profit margins, sometimes as low as 4%.

Batch Tracking and Quality Control

Batch tracking assigns unique IDs to products made under the same conditions, allowing for detailed tracking from production to distribution. This is especially important in industries like pharmaceuticals, food, automotive, and cosmetics, where compliance and quality are non-negotiable. The system can identify defective batches within just 4 hours, significantly improving operational efficiency. For example, 72% of food manufacturers report lower recall costs thanks to robust batch documentation. When issues arise, batch tracking simplifies recalls by pinpointing the affected batch and removing it swiftly. It also supports FIFO, LIFO, and FEFO methods, reducing waste and obsolescence. A mid-sized chemical company, for instance, saw a 35% boost in traceability and 40% faster recalls after implementing an ERP solution. Additionally, by integrating supplier data, the system ensures that all incoming materials meet quality standards.

Easy Integration with Current Tools

Procuzy ERP integrates effortlessly with your existing accounting software and business tools, saving you from a full system overhaul. This seamless connection reduces repetitive manual tasks and provides end-to-end visibility into the production process. By combining inventory management, production scheduling, and quality control into one platform, Procuzy ensures consistent and accurate data. Automated compliance features also cut down on manual errors, freeing up your team to focus on more strategic tasks. Together, these integrations create a smoother, more efficient manufacturing operation.

Industry Examples and Case Studies

Pharmaceuticals: Navigating Strict Regulations and Ensuring Quality

Pharmaceutical manufacturers operate in one of the most heavily regulated industries, where compliance and quality control are non-negotiable. Procuzy ERP offers a comprehensive solution by integrating raw material management, quality control, batch tracking, cost oversight, and finished product release into one streamlined system. This level of integration is critical for meeting FDA and other regulatory requirements.

“Pharmaceutical manufacturing software is a specialized solution which helps manufacturers maintain regulatory compliance, optimize production processes, and ensure product traceability.” – Procuzy

Take mCaffeine, for example – a personal care brand with pharmaceutical-grade manufacturing needs. By implementing Procuzy ERP, the company streamlined its entire supply chain, enhancing visibility and collaboration across teams. According to a 2025 Procuzy LinkedIn post, this approach led to a 15% increase in profits. On a broader scale, advanced manufacturing software like Procuzy ERP has been shown to improve production efficiency by up to 20% within the first year. These results highlight how tailored ERP solutions can simplify complex regulatory landscapes and drive measurable improvements in operational performance.

Food and Beverage: Managing Perishable Goods and Tight Margins

The food and beverage industry grapples with challenges like perishability, fluctuating demand, and slim profit margins. With inventory often accounting for over 70% of capital assets in food processing companies and approximately 1.3 billion tons of food wasted globally each year, efficient inventory management isn’t just beneficial – it’s essential for survival.

Procuzy ERP addresses these challenges head-on with tools like real-time stock monitoring, automated expiration tracking, and demand forecasting. For example, the system flags products approaching their expiration dates and triggers automated reorders based on historical trends, helping manufacturers avoid spoilage and stockouts. In cases of contamination, Procuzy ERP’s batch tracking capabilities allow companies to quickly identify and isolate affected products, minimizing both financial losses and reputational damage. These features make it a powerful ally in an industry where precision and timeliness are critical.

Furniture Manufacturing: Streamlining Complex Production Processes

Furniture manufacturing brings its own set of hurdles – dealing with diverse material requirements, custom orders, and multi-location operations. With the global furniture market valued at $630.55 billion in 2022 and expected to grow to $1.05 trillion by 2032, manufacturers need robust systems to keep up with demand.

Procuzy ERP simplifies these complexities by integrating production planning, multi-warehouse coordination, and resource management. For example, it aligns material requirements with production schedules to ensure timely assembly. A single piece of furniture might require components like wood panels, hardware, fabrics, and finishes – all of which Procuzy ERP tracks across multiple locations to prevent delays. Additionally, its collaboration tools enhance communication between design, procurement, and production teams, reducing errors and missteps. By optimizing resource allocation, the system helps manufacturers maximize equipment and labor efficiency, while built-in quality control ensures that finished products meet exact specifications before they leave the warehouse.

Customization and Setup Methods

Tailoring Procuzy ERP to Your Needs

Procuzy ERP is built with manufacturing diversity in mind, offering customization options that align with your unique workflows. Instead of forcing you to overhaul your processes, it molds itself to fit your operations. This adaptability is especially important when you consider that 88% of spreadsheets contain errors, leading to issues like stockouts, delays, and revenue loss in manufacturing.

The platform allows you to configure approval automation with multiple levels, matching your organizational hierarchy. This feature can dramatically streamline processes – automating purchase orders, for instance, can slash processing time by as much as 80%.

Job scheduling is another standout feature, enabling workflows to be tailored to factors like machine capacity, labor availability, and material lead times. Meanwhile, the system’s multi-level Bill of Materials (BOM) management handles even the most intricate product structures, offering detailed deviation reports and tracking material consumption.

Procuzy also transforms production data into actionable insights. Business intelligence dashboards deliver real-time metrics tailored to your industry – whether it’s batch compliance rates for pharmaceuticals, spoilage percentages for food and beverage, or material utilization rates for furniture manufacturing.

For quality control, the platform supports customizable tests that automatically approve or reject outcomes based on your pre-set criteria. This ensures digital quality checkpoints are seamlessly integrated into your production line, keeping your processes aligned with both internal standards and regulatory demands.

With these features, Procuzy ERP makes customizing and setting up your system straightforward, so you can focus on optimizing your manufacturing processes.

Setting Up for Success

Once you’ve tailored Procuzy ERP to fit your needs, the next step is a smooth and efficient setup. Start by analyzing your current systems to identify areas for improvement and potential integration points. This includes reviewing your technology stack, addressing data quality issues, and pinpointing workflow bottlenecks.

Establish a clear project scope with measurable goals and track progress using a deliverables-based approach. For instance, set benchmarks like reducing inventory costs by 20% or achieving a 98% on-time order fulfillment rate – both common outcomes for manufacturers implementing cloud-based ERP solutions.

During configuration, map your organizational structure within Procuzy, customize workflows to reflect your operations, and define user access controls. The platform’s seamless integration with existing tools ensures you can continue using familiar systems while gaining advanced capabilities.

Prepare your data for migration by cleaning and formatting it thoroughly. This step is critical, especially since 49% of procurement professionals still rely on email or spreadsheets for managing purchase orders. Transitioning from such outdated methods requires careful validation to ensure data accuracy.

“The Procuzy team provides exceptional support with deep process knowledge. Their expertise helped us streamline operations efficiently. Highly recommend their solution for manufacturers!” – Deepak H., Bighaat

Before going live, rigorously test the system to verify its functionality and the accuracy of your data. A phased implementation approach can minimize disruptions – start with non-critical processes or a single location, then expand gradually, using lessons learned to refine the rollout.

Employee training is a key part of the setup. Demonstrate how Procuzy’s features solve everyday challenges. For example, show warehouse staff how automated stock alerts prevent inventory shortages, or guide production managers in using real-time dashboards to make more informed decisions.

Even after the system is live, ongoing support ensures long-term success. Procuzy’s dedicated team offers expert guidance to help you continuously refine your setup. Regular reviews and user feedback sessions uncover new opportunities for optimization, helping your business evolve and potentially join the 95% of companies that report improvements after implementing ERP software.

sbb-itb-a748ddd

Benefits of Procuzy ERP Software for Manufacturing

Procuzy ERP offers measurable results, helping manufacturers cut costs and boost efficiency across their operations. By addressing key challenges in manufacturing, this platform delivers real improvements that reshape how businesses operate.

For instance, costs can drop by 20–30% through better resource allocation and reduced waste. Automating workflows further minimizes waste by 60%, shortens turnaround times by 1.5x, and lowers operational expenses by 22%. These improvements come from eliminating manual bottlenecks and providing real-time visibility into production processes.

Improved data accuracy and planning is another major advantage. Marico‘s Toral Patel shared her experience:

“Procuzy team is very helpful and responsive. With improved data accuracy, planning efficiency has significantly increased.”

Real-time insights also empower managers to act proactively, reducing machine downtime by 20–30% and increasing production throughput by 10–25%. This ability to anticipate and address potential issues ensures smoother, more efficient operations.

When it comes to quality control, Procuzy’s integrated systems deliver strong results. For example, an electronics manufacturer using a cloud-based ERP with built-in quality management reduced defects by 50%. Additionally, traceability features helped them identify root causes faster, cutting downtime by 20%.

Key Features and Their Benefits

Here’s a snapshot of how Procuzy ERP’s features translate into operational advantages:

| Feature | Benefit | Industry Use |

|---|---|---|

| Real-time Stock Tracking | Avoids stockouts, overstocking, and inefficiencies | All manufacturing sectors |

| Automated Stock Alerts | Prevents delays by notifying teams in real time | Time-sensitive industries like Food & Beverage, Pharmaceuticals |

| Multi-Location Support | Simplifies inventory tracking across multiple warehouses | Manufacturers with dispersed facilities |

| Batch Tracking & Barcoding | Ensures traceability and reduces errors | Pharmaceuticals, Food & Beverage |

| Cost and Wastage Tracking with Multi-level BOM | Reduces waste and improves cost management | All manufacturing sectors |

| Material Requirement Planning | Aligns production schedules and optimizes resource use | All manufacturing sectors |

Financial benefits extend beyond operational savings. Procuzy improves cash flow management by providing real-time financial data, enabling faster decisions. Inventory turnover increases by 20–40%, freeing up working capital that would otherwise be tied up in excess stock.

Another standout advantage is scalability. As your business grows, Procuzy adapts to meet your needs. Daily Objects‘ CXO Saurav A. shared:

“With Procuzy as a CXO, I am able to get meaningful insights on my manufacturing end and reports on work happening at the ground level.”

For industries requiring strict compliance, Procuzy simplifies documentation and audit trails, making it easier to meet regulatory requirements.

Procuzy also transforms team workflows. By automating repetitive tasks, employees can focus on strategic activities that drive growth and innovation. Arpit from Shivanika Foods highlighted this transformation:

“With Procuzy, we automated our entire process flow and gained a single tool for tracking all operations, significantly improving efficiency and visibility.”

Finally, the platform’s accessibility ensures that businesses of all sizes can benefit. Procuzy emphasizes this point:

“ERP software isn’t just for large enterprises anymore. Today’s cloud-based and modular solutions make it accessible for SMEs and midsized businesses as well – delivering powerful ROI with minimal disruption.”

Over time, these benefits build upon each other, helping manufacturers stay competitive and ready for future challenges as their operations expand.

Conclusion: Improving Efficiency with Procuzy ERP Solution

Today’s manufacturing world is more complex than ever, requiring integrated tools to simplify operations. Procuzy ERP steps in as a game-changer, tackling multiple challenges within a single platform.

Manufacturers using Procuzy ERP have reported impressive results: cutting production costs by 20–30%, reducing wastage by 60%, and achieving turnaround times 1.5× faster. Take Vishal Shere from ChopServe, for instance – his company saw a 45% boost in efficiency, expanded their supplier network by 90%, and slashed costs by 38%. Similarly, feedback from PKR Equipments and Shivanika Foods highlights how automating workflows with Procuzy ERP creates unified visibility across all operations.

By integrating key areas like inventory management, production planning, and quality control, Procuzy ERP breaks down data silos and grows with your business – whether you’re managing a single facility or multiple locations. This level of integration paves the way for smarter, more strategic modernization.

For manufacturers looking to stay ahead, Procuzy ERP offers cloud-based, industry-specific features that make modernization achievable. With the global ERP market set to hit $147.7 billion by 2025, adopting such a system ensures a competitive edge that lasts.

Switching from traditional methods to an ERP system like Procuzy isn’t just about keeping up – it’s about driving sustainable growth through better efficiency, lower costs, and clearer insights.

FAQs

How does Procuzy ERP solution work with existing manufacturing systems without requiring a full replacement?

Procuzy ERP is built to work hand-in-hand with your existing manufacturing systems, so you don’t have to worry about overhauling your entire setup. Through the use of APIs and middleware, it connects easily with tools such as supply chain platforms, inventory management software, and industrial equipment systems.

This setup enables real-time data sharing and synchronization, ensuring all your processes stay in sync. The outcome? Smoother operations, better efficiency, and minimal interruptions to the workflows you already rely on.

How does Procuzy ERP solution support manufacturers in highly regulated industries like pharmaceuticals?

Procuzy ERP equips manufacturers in regulated industries with tools for end-to-end traceability, automated quality control, and streamlined compliance documentation. These capabilities help businesses meet stringent industry standards while reducing the risk of manual errors.

The system also enhances inventory management by providing accurate tracking of raw materials and finished goods. This not only cuts down on waste but also simplifies product recalls when necessary. By refining these essential operations, Procuzy ERP allows manufacturers to concentrate on producing top-notch products while staying fully compliant with regulations.

How does Procuzy ERP software help food and beverage manufacturers avoid overproduction and stock shortages?

Procuzy ERP leverages AI-driven demand forecasting to help food and beverage manufacturers predict customer demand with accuracy. By diving into historical sales data and market trends, it delivers forecasts that support smarter production and inventory planning.

The platform offers features like automated stock level suggestions, safety stock calculations, and production scheduling. These tools work together to ensure inventory matches actual demand, reducing the chances of overproduction (which often leads to waste) or stockouts (which can disrupt operations and disappoint customers). This approach creates a leaner, more cost-efficient supply chain designed for the fast-moving food and beverage sector.