Looking for the best ERP system for manufacturers? Here’s what you need to know: Procuzy, SAP Business One, and Oracle NetSuite are three standout ERP platforms, each designed to tackle manufacturing challenges like inventory management, production planning, and operational efficiency.

Key Highlights:

- Procuzy: Tailored for small to medium manufacturers, offering real-time inventory tracking, production planning, and integrations with tools like WhatsApp. Proven results include a 60% reduction in wastage and 22% cost savings.

- SAP Business One: Ideal for larger operations with advanced inventory management, production planning, and deep customization options. Known for its robust integration capabilities and batch tracking.

- Oracle NetSuite: A cloud-based solution with strong inventory control, demand-based planning, and advanced manufacturing workflows. Suitable for businesses needing scalability and real-time insights.

Quick Comparison:

| Feature | Procuzy | SAP Business One | Oracle NetSuite |

|---|---|---|---|

| Target Audience | Small to medium-sized | Medium to large-sized | Medium to large-sized |

| Customization | Limited | Extensive | Extensive |

| Key Strength | Simple and affordable | Advanced features | Scalability |

| Integration | Standard tools | APIs, middleware | Cloud-based sync |

| Cost Efficiency | High | Moderate | Moderate |

Procuzy stands out for smaller manufacturers, while SAP Business One and Oracle NetSuite cater to more complex needs. Dive into the article for a detailed breakdown of each platform’s features and benefits.

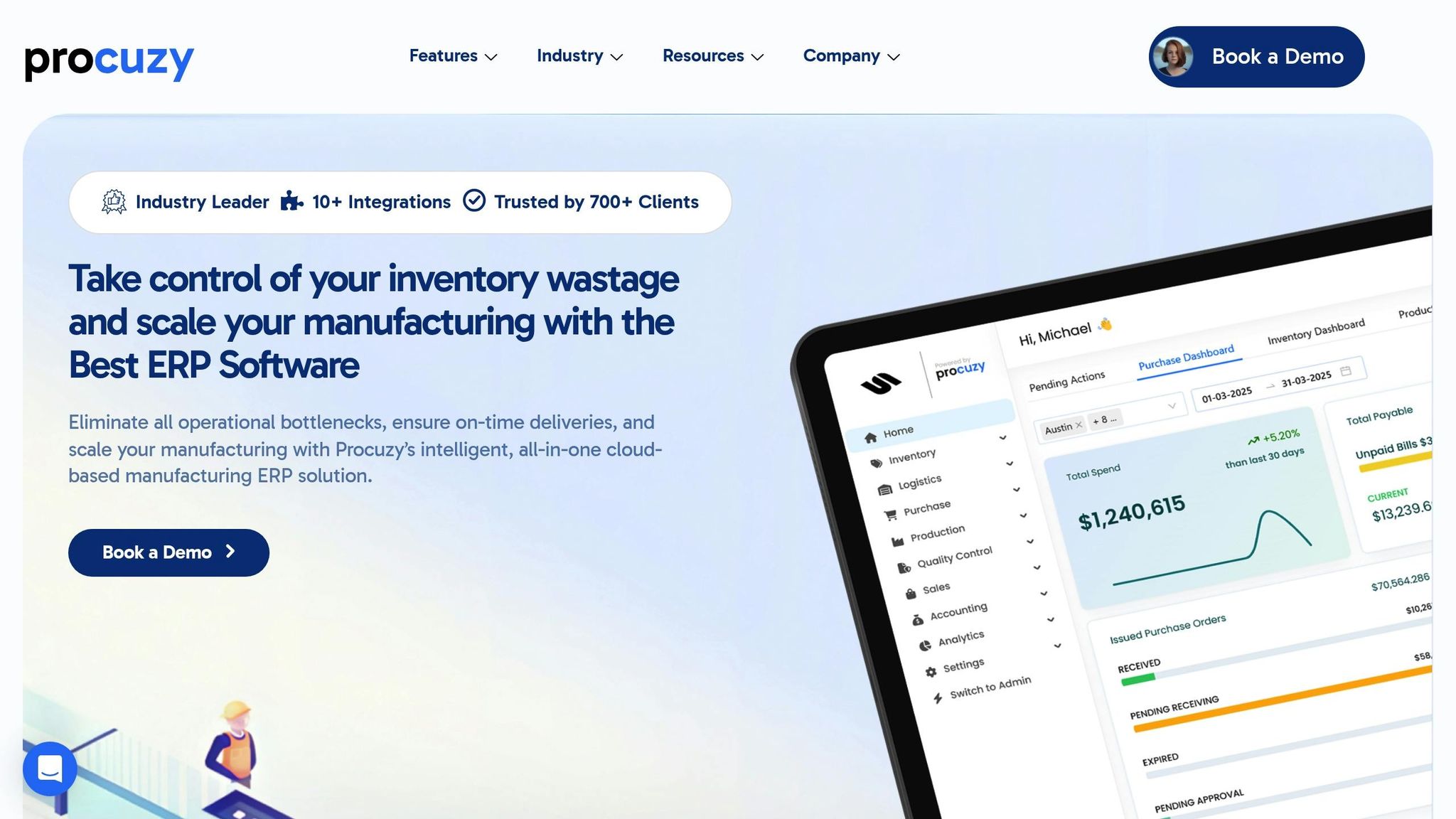

1. Procuzy

Procuzy is designed to tackle the unique challenges faced by manufacturers. This cloud-based platform zeroes in on manufacturing operations, offering tools that directly improve production efficiency and help cut costs.

Inventory Management

Managing inventory can be a headache for manufacturers, but Procuzy simplifies this with features aimed at reducing waste and optimizing stock levels. Its real-time inventory tracking, automated stock alerts, and reorder points help businesses avoid expensive stockouts or overstocking. For industries like food and beverage, batch and expiry tracking ensures food safety, while furniture manufacturers benefit from real-time inventory management across multiple locations. With these tools in place, companies can better plan production and minimize inefficiencies.

Production Planning

Procuzy’s production planning tools rely on MRP and manufacturing execution systems to handle even the most complex workflows. This capability has proven invaluable for businesses juggling multi-stage production processes. As Anurag Satyarth from Eggoz puts it:

“Procuzy’s factory setup module helps streamline their multi-stage manufacturing process and prevent wastage at each stage”.

To further enhance production, the platform includes predictive maintenance and machine scheduling features. These tools ensure equipment runs smoothly, reducing unexpected downtime and keeping production consistent while controlling costs.

Customization Options

Every manufacturing operation has its own set of needs, and Procuzy recognizes this by offering customizable workflows. The platform includes multi-level approval automation that can be tailored to fit specific business requirements. The development team works closely with users to implement these adjustments. Vrushali from the Business Supplies & Equipment Industry shares:

“I would like more customization options, but the tech team is very responsive”.

Real-world examples highlight this flexibility. Arpit from Shivanika Foods explains:

“Procuzy automated their entire process flow, providing a single tool for tracking all operations and significantly improving efficiency and visibility”.

Integration Capabilities

Procuzy doesn’t operate in isolation – it connects seamlessly with over 10 business tools to unify workflows and speed up processes. For instance, it integrates with WhatsApp for Smart RFQ Generation, making day-to-day operations more efficient. These integrations have led to tangible results, including a 1.5x faster turnaround time through automated workflows. Deepak H. from Bighaat highlights the hands-on support from the Procuzy team, noting their deep understanding of processes and how it helped streamline operations.

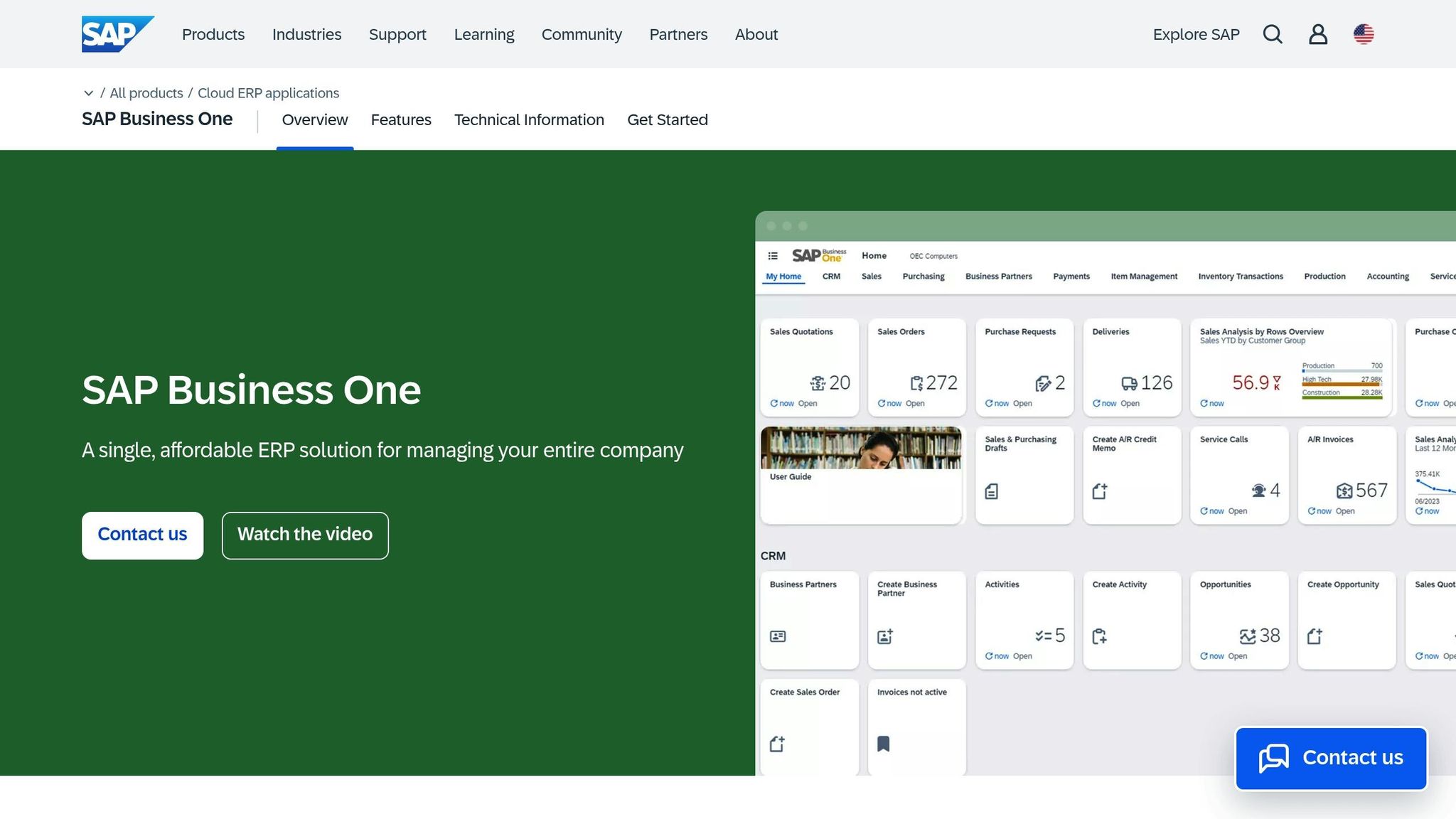

2. SAP Business One

After exploring Procuzy’s tailored features, let’s dive into SAP Business One – an enterprise-level ERP solution designed to tackle similar manufacturing challenges. This platform is packed with tools to manage complex business processes, offering manufacturers support across various operational areas.

Inventory Management

SAP Business One simplifies inventory management with demand forecasting tools that analyze past sales data and market trends. With real-time inventory tracking, businesses always know what they have in stock, where it’s located, and when to restock.

The platform supports several inventory valuation methods, such as standard costing, moving average, and FIFO, giving manufacturers flexibility in calculating costs. For industries like pharmaceuticals or food and beverage, where traceability is critical, SAP Business One offers batch and serial number tracking along with advanced source tracing capabilities.

Multi-warehouse management ensures smooth inventory coordination, while the Bill of Materials (BOM) feature supports both single- and multi-level structures for manufacturing items. The platform even includes product expiration date analysis, helping businesses trace products and components back to their origins.

“Efficient inventory management is the backbone of a successful business. Without the right tools, companies risk stock shortages, excess inventory, and inefficiencies that impact profitability.” – Alaa Mostafa, BE ONE

Production Planning

This system takes production planning up a notch with warehouse and bin location tracking, allowing teams to organize materials based on customizable criteria. Real-time analytics help manufacturers monitor quality control and predict potential issues by analyzing trends and historical data.

SAP Business One also integrates supplier quality checks and monitors batch quality throughout the production process. It streamlines procurement, from requesting quotes to paying invoices, while providing precise details on receipts, inventory, item locations, and outgoing shipments.

Customization Options

SAP Business One stands out with its customization capabilities. Businesses can use User-Defined Fields (UDFs) to add specific fields to tables and forms, capturing unique operational data. The platform also allows screen layout adjustments to fit user preferences.

Custom reports and dashboards provide tailored insights, visually presenting key performance indicators that matter most. Developers can use the Software Development Kit (SDK) to build custom applications and integrations for unique business processes. Additionally, businesses can customize document layouts for invoices and purchase orders, and workflows can be automated based on predefined rules. For example, one upholstery manufacturer transitioned from outdated systems to SAP Business One, gaining better project customization and tracking capabilities.

Integration Capabilities

SAP Business One seamlessly integrates with other systems through APIs, ETL tools, and middleware platforms. The SAP Business One Integration Framework (B1if) is a key tool for connecting SAP and non-SAP systems, as well as web and cloud-based applications.

The platform supports eCommerce integrations with Shopify, Magento, and WooCommerce, enabling real-time updates for customer orders, product data, inventory levels, and deliveries. CRM tools like Salesforce, HubSpot, and Zoho CRM can also sync customer and order data effortlessly. Payment processing is streamlined with services like PayPal, Stripe, and Square, automating invoicing and payment tracking. Shipping integrations with FedEx, DHL, and UPS further enhance fulfillment by providing automated delivery updates and real-time tracking. These integration capabilities ensure SAP Business One efficiently connects all layers of manufacturing operations.

3. Oracle NetSuite

Oracle NetSuite stands out as a cloud-based ERP solution designed to simplify manufacturing operations with real-time insights and streamlined processes. It provides manufacturers with a comprehensive inventory management system, offering a real-time view of stock across all sales channels. This helps reduce excess inventory and avoid costly stockouts, a critical feature given that 8% of global stock is lost or discarded annually. By utilizing demand-based planning, sales forecasts, and seasonality analysis, manufacturers can optimize inventory purchases, cut carrying costs, and ensure product availability.

Some of its standout features include multi-location fulfillment, automated replenishment, cycle counting, and advanced traceability. For industries like pharmaceuticals and food manufacturing, where precise stock control is non-negotiable, NetSuite’s multi-location fulfillment and traceability features ensure compliance and operational efficiency. The automated replenishment tool uses inventory levels, lead times, and sales forecasts to maintain optimal stock levels.

“I needed an inventory management system where everything is traceable. In NetSuite, I can see related records and every activity associated with a particular order – at the detail level – for auditing. Now we have valid, documented steps of what happened [with any given order].”

– Melvin Rodriguez, COO at Mielle Organics

The Item 360 Dashboard centralizes all item-related data, while cycle counting ensures accurate inventory records through routine, non-intrusive audits. NetSuite also integrates seamlessly with sales, procurement, and financial modules, providing a unified view of the entire supply chain. These tools work together to support synchronized production planning and efficient operations.

Production Planning

NetSuite’s production planning tools build on its precise inventory management to oversee manufacturing workflows from start to finish. With real-time visibility into every production stage, manufacturers can align output with demand and improve operational efficiency. The platform includes over ten manufacturing workflow tools, such as Assembly Item Records, Assembly Work Orders, Advanced Bill of Materials, Manufacturing Work In Process (WIP), and Manufacturing Routing. Additionally, the Advanced Manufacturing SuiteApp allows manufacturers to define work instructions, material usage, and schedules.

Its cloud-based production management system eliminates manual inefficiencies by automating production scheduling. The Engineering Change Order (ECO) feature ensures teams stay updated with the latest product specifications by managing and authorizing changes to Bills of Materials. These capabilities collectively enhance profitability, customer satisfaction, and operational performance.

Customization Options

NetSuite shines in its ability to adapt to specific business needs. Users can add custom fields to track unique data, such as specialized product SKUs or customer identifiers, or even develop entirely new applications within the platform. The system supports various record types for storing critical information, including customer, vendor, and employee records. Workflow automation further streamlines operations by triggering actions, like sending email notifications when orders are placed.

SuiteScripts enable developers to extend NetSuite’s functionality, creating custom applications and improving manufacturing efficiency. Custom dashboards and reports provide real-time insights, empowering leaders to make informed, data-driven decisions. These customization options not only reduce manual errors but also automate repetitive tasks and integrate workflows. Importantly, all modifications are supported by Oracle’s secure infrastructure and remain functional during bi-annual updates when handled by certified NetSuite partners.

Integration Capabilities

NetSuite’s integration framework connects manufacturing operations with other critical business systems, ensuring smooth data flow across departments. For example, inventory management integrates with financial reporting, supply chain management, and other key functions. The platform enables automated purchase orders based on inventory thresholds and supplier agreements, ensuring materials are available for production without overstocking.

Thanks to its cloud-based architecture, NetSuite supports real-time data synchronization, allowing manufacturers to make decisions based on up-to-date operational insights. The platform is available in various editions – Starter, Mid-Market, and Enterprise – catering to businesses of different sizes and needs. These integration capabilities further solidify NetSuite as a comprehensive ERP solution, setting the stage for an evaluation of its overall strengths and weaknesses.

sbb-itb-a748ddd

Advantages and Disadvantages

Let’s break down the key benefits and considerations of Procuzy, especially for smaller manufacturers. The table below highlights the main points:

| Key Advantages | Main Considerations |

|---|---|

| • Affordable solution tailored for small to medium manufacturers • Easy to implement without needing a dedicated IT team • Proven results: 60% reduction in wastage and 22% operational cost savings • Faster processes: 1.5x quicker turnaround times • Full operational transparency with 360° real-time inventory tracking • Integrates smoothly with existing business tools |

• Limited scalability for larger enterprises • Works with standard business tools but struggles with highly complex integrations • Primarily designed for smaller businesses • Fewer options for advanced customization |

Procuzy’s Unique Position

Procuzy stands out by addressing the specific challenges faced by smaller manufacturers. It offers a powerful yet straightforward platform that avoids unnecessary complexity. Users have reported tangible improvements. For example, Mohan from PKR Equipments shared:

“Procuzy automated our procurement and inventory tracking, reducing errors and improving efficiency”.

This feedback underscores how Procuzy enhances operational efficiency and visibility, which is essential for lean teams that prioritize production over managing complicated IT systems.

Scalability Considerations

While Procuzy is an excellent fit for small to medium-sized operations, its scalability has limits. It can handle modest growth, but manufacturers planning rapid expansion may need to assess whether its features align with their future needs. Its integration capabilities work well with standard business tools but may not accommodate highly complex enterprise systems.

Industry-Specific Strengths

Procuzy also shines in addressing specific industry needs. For instance:

- Pharmaceutical Manufacturing: The platform integrates seamlessly with Quality Management Systems, offering a unified dashboard to streamline operations.

- Food and Beverage Production: Procuzy provides real-time tracking, automated stock replenishment, and expiration date monitoring, helping prevent spoilage while ensuring compliance with food safety standards.

Ayush Saxena from Staschem highlighted these benefits, saying:

“Procuzy transformed our production workflow with real-time batch tracking and inventory optimization”.

These examples show how Procuzy tailors its features to meet the unique demands of different manufacturing sectors, making it an effective tool for solving specific operational challenges.

Conclusion

Procuzy stands out as a results-oriented ERP solution specifically designed for manufacturers, with a proven track record of delivering measurable improvements. Trusted by over 700 clients, it has achieved outcomes like a 60% reduction in wastage, 1.5x faster turnaround times, and a 22% drop in operational costs.

This software addresses manufacturing challenges head-on, offering tools for inventory management, production planning, and operational visibility. For instance, ChopServe reported a 45% boost in efficiency, 38% lower costs, and a 90% expansion in its supplier network. Toral Patel from Marico highlighted the platform’s impact:

“Procuzy team is very helpful and responsive. With improved data accuracy, planning efficiency has significantly increased”.

For small- to medium-sized manufacturers, Procuzy strikes the right balance between functionality and ease of use. It provides real-time inventory tracking, automated procurement, and integrated quality management, all without requiring extensive IT resources.

The platform’s specialized features cater to various industries – whether it’s quality management for pharmaceuticals, expiration tracking for food and beverage, or batch monitoring for chemical manufacturing.

With its practical and efficient approach, Procuzy empowers manufacturers to streamline operations and scale effectively. As Saurav A. from Daily Objects shared:

“With Procuzy as a CXO, I am able to get meaningful insights on my manufacturing end and reports on work happening at the ground level”.

Procuzy’s ability to deliver tangible results makes it a standout choice for manufacturers looking to enhance productivity and grow seamlessly.

FAQs

What features make Procuzy a great choice for small to medium-sized manufacturers?

Procuzy caters specifically to small and medium-sized manufacturers, offering tools that make managing operations easier and more efficient. Its inventory management system stands out by helping businesses keep track of stock levels, anticipate demand, and automate reordering. This means you’re less likely to deal with overstocked shelves or unexpected shortages, keeping your operations running smoothly.

Another key feature is its planning and scheduling tools, which seamlessly sync production schedules with procurement plans. This real-time alignment boosts efficiency, ensures resources are used wisely, and supports smarter decision-making. These features are designed to help smaller manufacturers simplify their workflows and grow their operations with ease.

How does integrating WhatsApp with Procuzy improve manufacturing processes?

Procuzy’s integration with WhatsApp brings a game-changing level of real-time communication to manufacturing operations. By connecting teams, suppliers, and customers in one seamless platform, it helps cut down delays, speeds up decision-making, and ensures everyone stays on the same page with the latest updates.

This feature allows businesses to respond to customer inquiries faster, simplify order processing, and work more closely with suppliers. The result? Happier customers, lower operational costs, and better overall productivity. In fact, many manufacturers have seen smoother communication and a noticeable boost in sales after adopting this integration.

Does Procuzy scale effectively for growing manufacturing businesses?

Scaling up operations can be an exciting milestone for manufacturers, but it often comes with its own set of challenges. As businesses grow, managing inventory, keeping track of data, and adjusting to new workflows can become more complex, requiring extra attention to maintain efficiency and accuracy.

For businesses experiencing rapid growth, it’s crucial to make sure that Procuzy’s features keep pace with these changing demands. If configurations and processes aren’t updated regularly, scalability might suffer, potentially causing delays or increased operational expenses. The good news? With thoughtful planning and regular fine-tuning, Procuzy can seamlessly evolve to support your growth journey.