Industries / Cosmetics

Manage Your Cosmetics Inventory Effortlessly with Procuzy

Track your stock, shelf life, and automate purchasing decisions based on thresholds and sales predictions. Procuzy’s inventory management module is designed to handle the complexities of your cosmetics business, ensuring high demand fill rates.

Streamline Your Supply Chain

Procuzy’s integrated solution helps optimize your supply chain across procurement, inventory, production, quality control and sales.

- Complete visibility and control over factory costs

- Detailed inventory ledgers that automatically track all inventory transactions

- Streamline end-to-end planning, ensuring the right inventory levels

- Monitor real-time stock movements across locations

- Optimize procurement workflows and timelines

Features

Maintain Quality and Compliance

Ensuring high quality standards of your cosmetics products is paramount in the highly regulated beauty industry.

- Automate quality tests and retests to ensure you maintain high standards

- Track and monitor all details regarding your inventory batches

- Maintain consistent quality standards across facilities

- Get detailed BMRs for complete visibility into manufacturing details for the batch

Intelligent Identification of Product Deviations

Always identify and address non-conformities, maintain detailed records, and stay ahead of the latest industry regulations.

- Easily maintain BOM estimates to identify deviations across material consumption, production costs, and outputs

- Seamlessly integrate manufacturing and quality modules for end-to-end visibility

- Smart alerts to track reasons behind production deviations

- Implement immediate corrective actions

Detailed Production And Materials Planning

Align your procurement, inventory and production teams to optimise flows, minimising waste, and ensuring you always have the right materials on hand.

- Automatically calculate production and procurement requirements to meet demand

- Synchronize your sales, production, and procurement plans ensuring optimal allocation of resources

- End-to-end visibility into sales, production, and procurement status

- Optimize resource allocation across production cycles

- Ensure you meet the requirements of multiple sales orders

Intelligent Insights Powering Your Operations

With Procuzy, you can get all the insights into your factory operations in one place.

- Monitor real-time performance metrics

- Generate comprehensive analytical reports

- Access customizable dashboards

- Make data-driven operational decisions

Stay Ahead of Trend Shifts

The cosmetics industry is constantly evolving, with consumer preferences and market trends shifting rapidly.

- Dynamic stock thresholds based on historical sales and production data

- Forecast inventory requirements based on sales orders and demand forecasts

- Adapt quickly to market changes

- Easily identify maximum production feasibilities and raw material shortages

- Optimize inventory levels based on trend analysis

Elevating Quality Compliance Through Smart Technology

Break free from complicated quality assurance practices with intelligent compliance management

Dynamic Production and Materials Orchestration

Break free from rigid production plans Procuzy's dynamic chemical inventory management software.

Intelligent Insights Powering Your Operations

Procuzy's analytics and reporting modules can help you make the right data driven decisions.

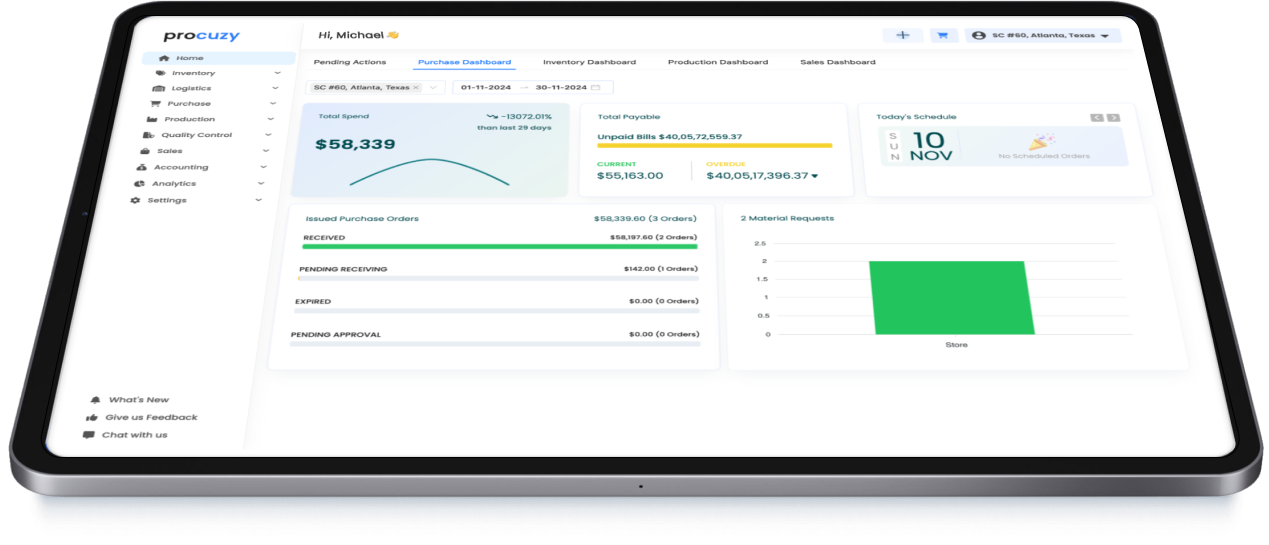

Seamless Decision Making through a centralised dashboard

Procuzy’s software centralizes data from procurement, inventory, production, and sales into one tailored dashboard. Get actionable insights with custom dynamic filters, and track production trends across products and locations.

More questions about our tools and services?

Cosmetic inventory management is crucial for ensuring product quality, regulatory compliance, and efficient supply chain operations and procurements.

When selecting ERP software for a beauty and cosmetics business you should keep into consideration features like batch tracking, regulatory compliance management, integration with existing systems, real-time inventory tracking and a unified dashboard for convenient access.

Important key modules in cosmetics software include inventory management, batch tracking & traceability, BOM management, regulatory compliance, sales & order analysis, procurement & supply chain management and financial tools integration.

Although there are a number of software in the market for cosmetic inventory management, Procuzy trumps them as it focuses specifically on the needs of manufacturers and its ability to provide customized solutions for its users keeping updated with the current marketplace.

Procuzy enhances cosmetic manufacturing by providing real-time inventory tracking, batch traceability and automated compliance management. Its cloud-based system helps manage the entire Bill of Material and optimize procurement.